It can be estimated that every year, in the United States alone, about 900,000 deaths can be prevented if there was no shortage of organs, or if transplants were not delayed and readily available to patients of organ failure. In fact, a Forbes study has ranked the lack of tissue transplants as one of the leading causes of death in America.

Researchers at Prellis Biologics aimed to resolve this crisis using the 3D printing technique, but a faster version of it. The SFO-based company, in 2017, claimed to have reached unprecedented speeds, while printing quality human tissue, along with its active capillaries. This innovation could pave the way for the large-scale manufacture of tissues in the future.

Regarding this, co-founder of Prellis Biologics, Melanie Matheu, said, “A major goal in tissue engineering is to create viable human organs, but nobody could print tissue with the speed and resolution needed to form viable capillaries. At Prellis, we’ve now developed that technology, paving the way for important medical advances and, ultimately, functional organ replacements.”

Drawbacks of Conventional 3D Printing

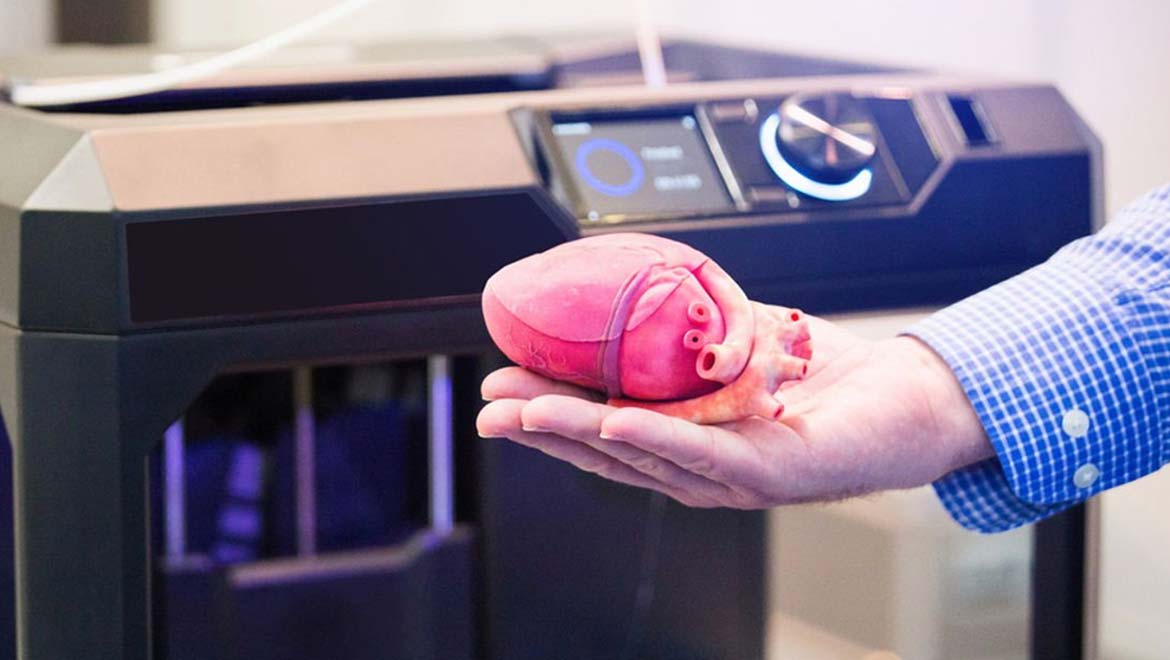

A few years ago, with the introduction of techniques like 3D printing (i.e., organs such as the skin, bladder and blood vessels successfully printed via a 3D printer and transplanted into a recipient), it was expected that a large burden could be taken off acquiring these live human tissues for transplantation. But it was not that simple.

Traditional 3D printing of organs has shown certain limitations in the past. (Image Source: Advanced Solutions)

Why? 3D printing and organ transplant has known to be time-consuming. The technique is a long-drawn process, where, during printing, the tissues require a constant supply of oxygen and other nutrients, a lack of which will cause the death of cells in 30 minutes or so.

This concern was overcome with vascularization/supplying blood through capillaries to the living tissues, as part of the process. Traditionally, thin sheets of biological material are printed, using this method, that is constantly nourished.

However, yet another issue concerned scientists around the world — the slow rate of 3D bioprinting. In the time that the entire procedure was completed, which could take weeks, the living components involved would long be dead.

Improved Technique of 3D Printing Viable Human Organs

As described by the Prellis team in their white paper, there are four parameters to be considered while 3D printing viable human tissues: resolution, speed, complexity, and biocompatibility.

High resolution was a critical requirement for designing intricate capillaries and microcellular elements. After much deliberation, the study used a resolution of 0.5 microns (10 times smaller than regular bio-printers) for the capillaries.

Speed was of vital importance due to the cells’ various differentiation stages, and low survival time. A light-based polymerization technique called 3D Multi-Photon Holography was used to engineer quick three-dimensional printed structures. An entire block of tissue was formed, by this method, in less than 12 hours.

Todd Huffman, CEO of 3Scan, a digital tissue imaging and data analysis company, explained, “Vasculature is a key feature of complex tissues and is essential for engineering tissue with therapeutic value. Prellis’ advancement represents a key milestone in the quest to engineer organs.”

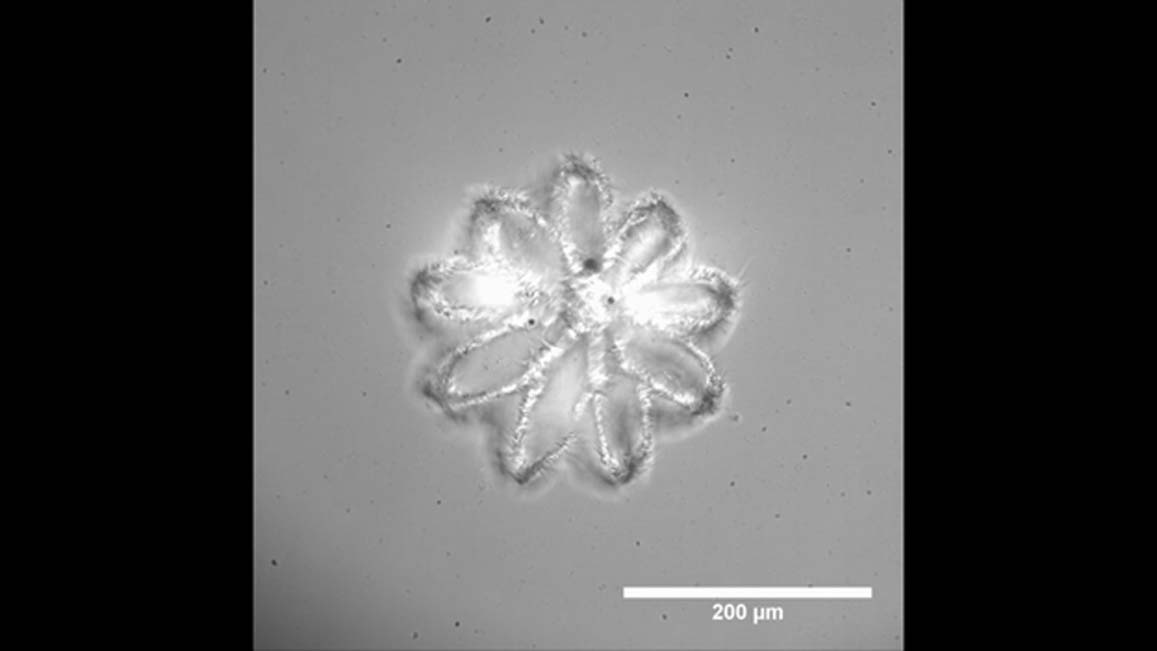

3D printing of human tissue at record speed was achieved by scientists at Prellis Biologics. The tiny particles, like red blood cells, are moving through printed capillaries, in this real-time video. (Source: 3Ders.org)

Complexity was another feature that was a requirement in this research. Combined with the speed and resolution, the investigators were able to achieve a complex vasculature and scaffolding that, in the end, allowed the human tissue to survive. They did this with the help of 3D control of structural polymerization, and its capacity to print on other parts of the previously-printed material.

Biocompatibility or creating tissue that is compatible with living cells, was, and has always been, of “paramount importance.”

With all these factors, the Prellis group used holographic 3D printing, and for the first time ever, engineered sub-cellular structures with the help of their bio-ink.

3D printing using holographic technology. (Source: Prellis Biologics)

Future of the Technology

This revolutionary advancement could be applied to several areas of medicine and pharmacology, including being the basis of replacement organs for transplantation, and also drug discovery and toxicology testing.

It has been predicted that 3D printing, in general, will grow at an exponential rate (approx. $10 billion by 2020); the 3D printing market is already estimated to be at $500 million.

The problem of organ failure and transplantation needs to be addressed to avert a healthcare crisis, and in this speedy new and improved technique, we may have finally found a solution!

Top Image: Prellis Biologics creates a viable means for large-scale tissue production. (Source: Prellis Biologics @ Twitter)

References

Could 3D printing solve the organ transplant shortage? 2017, The Guardian, https://www.theguardian.com/technology/2017/jul/30/will-3d-printing-solve-the-organ-transplant-shortage, (accessed 5 July 2018)

New tech allows much faster 3D-printing of human tissue with capillaries, 2018, New Atlas, https://newatlas.com/3d-printed-human-organs-capillaries/55173/, (accessed 9 July 2018)

Matheu, M. et al. (2018), Human Organ and Tissue Engineering: Advances and Challenges in Addressing the Medical Crisis of the 21st century

Prellis Biologics Achieves Unprecedented Speed and Resolution in 3D Printing of Human Tissue With Capillaries, 2018, Synbiobeta, https://synbiobeta.com/prellis-biologics-speed-and-resolution-in-3d-printing-of-human-tissue/, (accessed 10 July 2018)

No comment