Many modern batteries use lithium, an earth metal, as a medium for energy storage. Earth metals were chosen in the course of solid battery development as their ions have many favourable properties for such applications. Lithium has a high specific capacity (3860 mAhg/m) and also has relatively high electronegativity. However, raw lithium for new batteries is mined and used at ever-increasing rates, which may affect its cost in the long run. Lithium-ion batteries also carry risks of failure, which can damage device lifespan at best and cause harm or injury at worst. There are a few alternatives to lithium in terms of ion-based batteries; a prominent example is sodium ion battery.

What is a sodium ion battery?

Sodium-ion batteries were in fact developed prior to their lithium-based counterparts. This earth metal is also much more abundant and could be sourced for energy-storage solutions much more easily. However, it also has drawbacks when compared to lithium, the least of which is its greater atomic mass; therefore, a sodium battery would have an ion density that would be less than an equally-sized lithium battery. Sodium also has a reduced specific capacity compared to that of lithium (about 1100 mAhg/m). On the other hands, some researchers believe that optimised battery technology would overcome these disadvantages, and that the reduced overall costs would justify the work involved in this. In addition, sodium, when paired with high-energy electrodes, have demonstrated greater electrochemical stability while discharging compared to lithium.

The main disadvantage of sodium ion battery is that they suffer from the issue of impaired or reduced capacity over time as a result of charging. This is because charging is related to a phenomenon known as dendrite formation. Dendrites, in electrochemical terms, are rough, uneven deposits of the ion-donating material (i.e. sodium in this example) which form on the surface of an electrode within a cell. Earth-metal batteries are particularly susceptible to this effect as these elements begin to form dendrites at current densities far lower than those associated with dendrites in other materials. Even minor imperfections within a battery’s structure, such as those that produce inconsistent resistance, can induce dendrite formation in lithium or sodium batteries. This resistance acts on the interface between a battery’s anode and its electrolytes, and leads to an uneven concentrations of electric field lines as the battery accepts a charge. This in turn intensifies dendrite formation over time, until at least one can bridge the space between the cathode and anode, which short-circuits the cell.

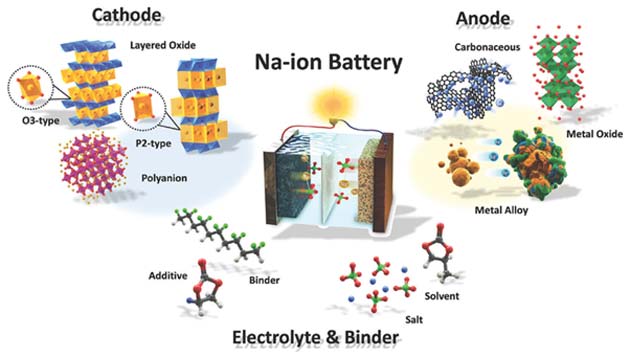

Illustration of a Na-Ion battery system. (CC BY 3.0)

Short-circuited cells can cause battery failure by impacting on its capacity. This is done when ‘completed’ dendrites break or melt in the interface, which negates the electrical functionality of the material around it. Alternatively, short circuits can cause more catastrophic battery failures, including those that end in combustion or explosion. Sodium batteries may be more susceptible to both types of failure than lithium-powered versions. Therefore, battery manufacturers who wish to exploit the increased availability of sodium need to develop all their components so as to limit these risks. As a result of this, the increased optimisation of the electrode/electrolyte interface, known as the solid-electrolyte interface or SEI, is a valid target for researchers working in this area. However, there are relatively few studies that have demonstrated improvements in the SEI for sodium batteries.

Improving performance

Most work that aims to stabilise the SEI in non-lithium batteries attempts to apply the strategies employed to do the same for lithium-ion batteries. These include the development of electrolyte additives. These compounds, which include dioxanes, sultones, vinylenes or functional ionic liquids, act to protect the electrodes and manage charging-related volume changes within them. Another tactic is to add salts that react to produce halides in the SEI. For example, the addition of LiFSI to a lithium battery would result in the production of lithium fluoride in the SEI. The presence of this halide has been found to improve battery lifespans at a range of current densities in some recent studies. When this technique was applied to sodium batteries, it increased columbic efficiencies to as much as 99 percent.

Therefore, a team of researchers from the School of Chemical and Biomolecular Engineering at Cornell decided to investigate the potential of a sodium bromide (NaBr) additive in stabilising the SEI in a sodium ion battery. They used a battery with electrodes made of solid sodium and an SEI made of NaBr. They found that running this battery resulted in an even, 2-12 micrometer coating of NaBr on the anode. An inspection of the coated anode using direct visualisation and spectroscopy techniques demonstrated that this coating decreased the energy of ion transport across the SEI and effectively prevented dendrite formation.

Sodium bromide powder. (Public Domain)

Using a form of analysis based on joint density-functional theory (JDFT), the team also found that the NaBr treatment also resulted in an extremely low barrier of ion diffusion between the electrodes – only about 0.02 eV per atom of sodium. This barrier was lower than that for LiBr or LiF, and also compared well to that of magnesium (a reference standard for ion transport efficiency). The team also used X-ray and scanning electron microscopy imaging to demonstrate the positive effect a NaBr coating had on the surface of the solid sodium anode. The coating helped to prevent roughness on the surface of the anode, which has the potential to prevent the induction or propagation of dendrite formation and thus conserve battery function.

Researchers in the area of battery technology have recently resumed their interest in sodium as an alternative form of energy storage. Lithium-ion technology is undoubtedly popular and widespread, but sodium is a similar earth metal that is far more abundant and could keep solid battery production relevant and viable in the future. However, sodium batteries are also highly susceptible to failure due to dendrite formation between electrodes while charging. A team from Cornell demonstrated that the addition of a stabiliser (sodium bromide) to the SEI of an experimental sodium-based battery, as is done with lithium batteries, may improve its stability. This treatment also had minimal impact on basic battery functions (i.e. the flow of ions from cathode to anode). Research such as this may help sodium to reclaim its position in the production of commercial high-capacity batteries, with potentially positive knock-on effects on economic and ecological concerns.

Top image: Sodium (Public Domain)

References:

Choudhury S, Wei S, Ozhabes Y, Gunceler D, Zachman MJ, Tu Z, et al. (2017) Designing solid-liquid interphases for sodium batteries. Nature Communications. 8:(1). pp.898.

Seh ZW, Sun J, Sun Y, Cui Y. (2015) A Highly Reversible Room-Temperature Sodium Metal Anode. ACS central science. 1:(8). pp.449-55.

Choudhury S, Archer LA. (2016) Lithium Fluoride Additives for Stable Cycling of Lithium Batteries at High Current Densities. Advanced Electronic Materials. 2:(2). pp.1500246-n/a.

No comment